ThyssenKrupp Stairlifts B. V.

NOVOPLAST produces injection-moulded parts and complete modules for ThyssenKrupp Stairlifts B.V.'s latest NCF product generation.

The project at a glance

- Everything from a single source

- Complex and closely tolerated covers

- Printed and lasered transparent parts

- Optimal support in laying out and designing the components with respect to material and processing technology.

- Documentation and feasibility, PPAP process compliance

- Maximum efficiency in developing injection moulding tools

Product

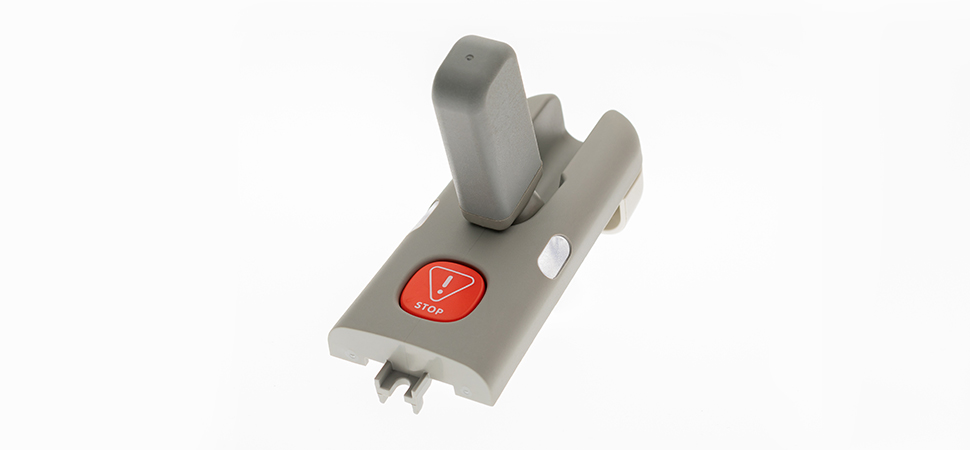

NOVOPLAST AG produces injection-moulded parts and complete modules for the latest generation of NCF products for ThyssenKrupp Stairlifts B.V., a world leader in the manufacturing of lift chairs and lift systems. The product consists of more than 300 components, 34 of which are manufactured in our production facilities.

Challenge

ThyssenKrupp Stairlifts B.V. wanted to work with as few suppliers as possible in this project. Therefore, this supplier had to offer comprehensive services such as development support, production, procurement and Kanban delivery from a single source. The timing was ambitious too: the project had to be coordinated and implemented within 13 months, from the order to the pilot series.

With this project, for the first time, the customer was dependent on setting up and approving sampling according to the PPAP process (Production Part Approval Process). This included a wide variety of documents and evaluation of the CpK value for 70% of the components (process capability indices: key figures for evaluating a process statistically).

Product solution

Thanks to the large vertical range of manufacture, which at NOVOPLAST goes far beyond the core competency of injection moulding, ThyssenKrupp Stairlifts B.V. was able to optimally cover the manifold needs in order to procure complete solutions. The customer received everything from a single source, from complex and closely tolerated covers to printed and lasered transparent parts.

Thanks to our many years of experience, ThyssenKrupp Stairlifts B.V. was able to receive optimal support in the development phase of the new generation of products, in the layout and design of their components in terms of material and processing technology.

In this phase, the cornerstone was laid for the documentation and feasibility of the components so that the PPAP process could be adhered to and retained. This made short and efficient sampling possible.

"Out of 34 items, only 1 injection moulding tool had to be put into a further iteration loop before being finally approved by the customer."

Through well-rehearsed processes within the supply chain, injection moulds for this project are quickly procured in China, Italy, Switzerland and Germany, sampled on site and brought to series production under constant monitoring by NOVOPLAST.

In doing so, entire modules, including the procurement of electronics, mechatronic components, cables, displays and switches, etc. are assembled and checked before delivery.

Weitere Referenzen

Roche Diagnostics MagNa Pure 24

NOVOPLAST manufactures the intake systems (racks) for Roche Diagnostics's MagNa Pure 24, a fully automatic clinical nucleic acid extraction system.

Read moremerck sigma-aldrich international gmbh

NOVOPLAST, Sial, Helbling and Metrohm have been working together closely to develop an intelligent chemical bottle closing system for Merck Sigma-Aldrich International GmbH.

Read more